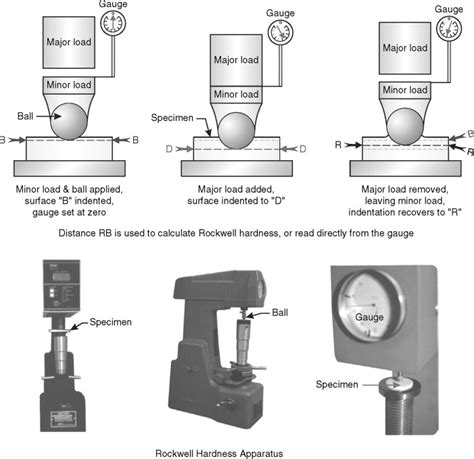

how to do rockwell hardness testing|rockwell hardness testing procedure pdf : traders Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied light (minor) load (SET point). Resultado da 24 de dez. de 2017 · Tumblr is a place to express yourself, discover yourself, and bond over the stuff you love. It's where your interests connect you with .

{plog:ftitle_list}

WEBFoto: Bruno Soares. A edição 2023 do show Tardezinha do cantor Thiaguinho acontecerá em duas datas na Neo Química Arena em São Paulo, no bairro de Itaquera. O evento .

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

The Rockwell hardness test is a measuring system used to determine how resistant a material is to another object. Grab this complete guide.

rockwell hardness testing procedure pdf

Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied light (minor) load (SET point).The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators and the methods used are following proper test technique and practice. The precise nature and exactness of a Rockwell test . Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness definition, testing procedure.

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .

Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. We depend on the data produced to verify heat treatment, structural . Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing. Inadequate surface preparation can lead to failed tests or false readings.

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

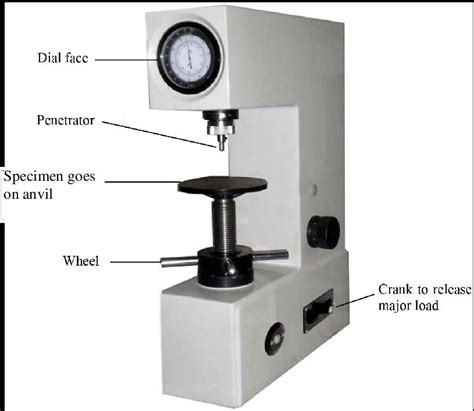

Rockwell Hardness Test. The Rockwell hardness test evaluates the hardness of a material by measuring the permanent depth of indentation due to an applied concentrated load. The higher the number on the Rockwell hardness scale, the harder the material. The test is conducted by applying a minor force of 10 Kg using a diamond cone or a steel ball .A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a measuring transducer. The DuraJet, ZHR Touchscreen and ZHR8150CL models are software controlled hardness testing machines with automatic . In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.

The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of measuring the resolution of a material to a 0.001″. Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. Rockwell Hardness Test. While hardness testing does not provide a direct assessment of product or raw material performance qualities, hardness correlates directly to qualities like strength and wear resistance. .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .

For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.

Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .Caution: The hardness tester will not open to its full capacity unless the elevation screw is allowed to pass through a hole on the support surface. 3. Bolt tester to support surface securely using the 4 each hex head bolts or use longer 10-1.5mm bolts if required. Be sure tester is level both front/back and left/right to 0.002 in/in.

how to measure methane gas

methane gas calibration kit

Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive .

Rockwell Hardness Testing. Because of its low force, high speed, and nondestructive nature, Rockwell hardness testing commonly is used on all sizes of tubing. To perform a Rockwell test successfully, you must consider several factors. Surface Finish. The surface finish for Rockwell testing must be smooth and uniform to obtain an accurate .

Interpreting the Results with a Rockwell Hardness Test Chart. A Rockwell hardness test chart provides a reference for interpreting the recorded indentation depth into a corresponding hardness value. The chart typically includes different scales (e.g., Rockwell B, C, and others) and corresponding hardness values based on the load and indenter used.🕑 Reading time: 1 minute Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the [.]

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

rockwell hardness testing procedure

rockwell hardness testing pdf

Rollover: Sem exigência. Menores odds: 1.01. Quero Bônus Visitar o site: 19: Dafabet: Bônus até R$750. Rollover: 5x depósito + bônus. Menores odds: 1.50. Quero Bônus Visitar o site: 20: Sambabet: Bônus até R$1.000 com código SITEDEAPOSTAS. Rollover: 6x bônus. Menores odds: 3.00. . Ver mais

how to do rockwell hardness testing|rockwell hardness testing procedure pdf